When it comes to setting up a safe and efficient wood stove system, your choice of stove pipe plays a crucial role. Among the most common options are single wall and double wall stove pipes—but how do you know which one is right for your home?

Each type has its unique advantages, limitations, and safety requirements. Whether you’re installing a new stove, upgrading an existing flue system, or simply trying to understand what meets NFPA standards or CSIA recommendations, knowing the difference can impact your heating efficiency, clearance requirements, and even insurance coverage.

In this guide, we’ll break down the key differences between single and double wall stove pipes, their pros and cons, and which one best suits your specific heating setup. From installation tips to safety standards, this article will help you make an informed, fire-safe decision.

Understanding the Basics of Stove Pipes

Before choosing between a single wall and a double wall stove pipe, it’s essential to understand how stove pipes work and their role in a wood stove heating system. A properly installed stove pipe is key to ensuring your system operates safely, efficiently, and in compliance with building codes.

What Is a Stove Pipe?

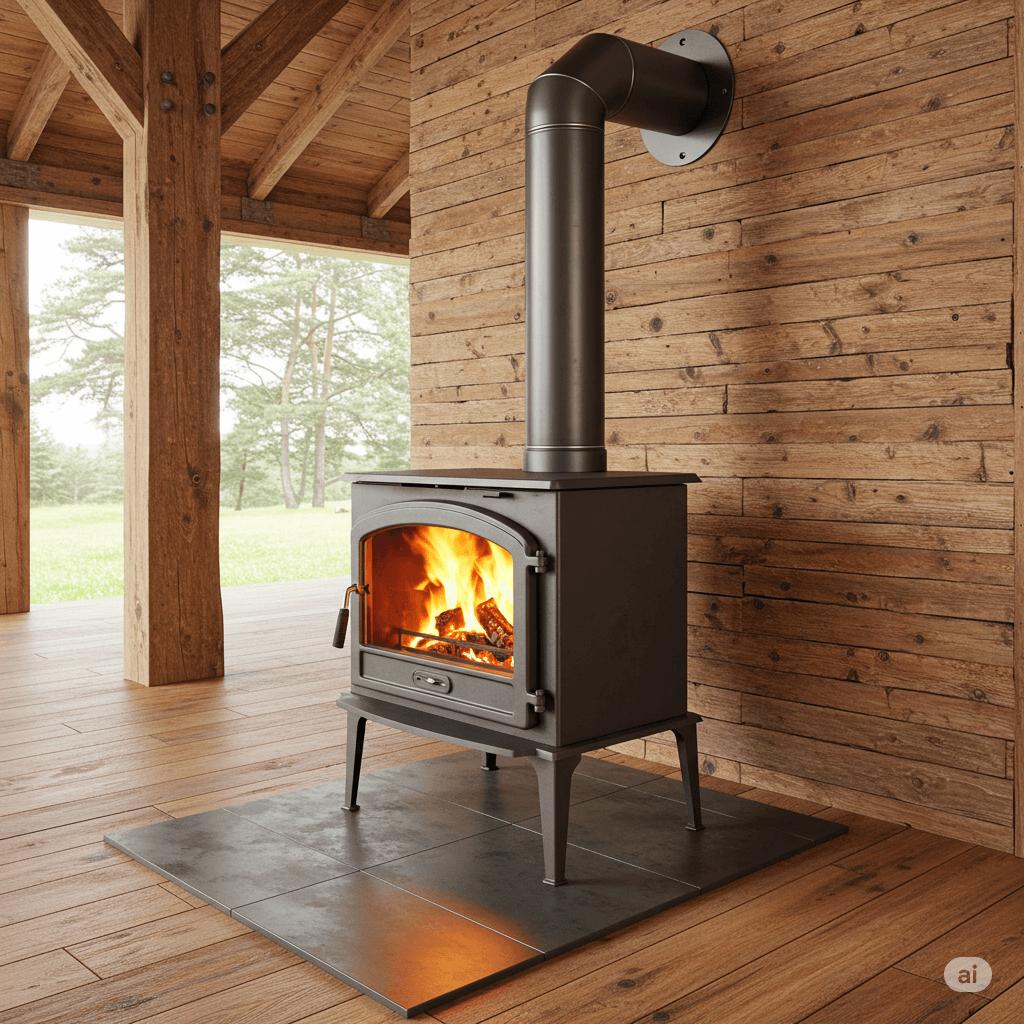

A stove pipe—also known as a chimney connector—is the section of piping that connects your wood stove to the chimney. Its primary job is to carry smoke, gases, and byproducts of combustion from the stove to the vertical chimney pipe that vents outside the home.

Unlike a full chimney system, the stove pipe is exposed inside the living space, which allows it to radiate additional heat into the room. However, this also means it’s subject to strict safety and clearance regulations.

Purpose of a Chimney Connector

The chimney connector bridges the gap between the stove and the chimney or flue system. It’s a critical part of your wood stove setup, and choosing the wrong size or material can lead to poor draft, smoke leakage, and dangerous creosote buildup.

Whether you’re using a single wall or double wall pipe, its function remains the same: to safely transfer exhaust gases to the insulated chimney while minimizing heat loss and ensuring a proper draft.

Role of UL 103 HT Certification

When shopping for stove pipe components, look for those with a UL 103 HT listing. This certification means the pipe is rated for high temperatures up to 2100°F and meets stringent safety standards for wood-burning appliances.

Using UL-listed pipe ensures you’re installing parts that:

-

Comply with NFPA 211 guidelines

-

Are recognized by insurance providers

-

Offer maximum safety in long-term operation

Why Choosing the Right Pipe Matters

Your stove pipe directly impacts:

-

Fire safety (especially clearance from combustibles)

-

Heating efficiency (heat retention and airflow)

-

Compliance with building codes from the NFPA and recommendations by the Chimney Safety Institute of America (CSIA)

Selecting the correct pipe type based on your stove’s location, usage, and local regulations ensures optimal performance and peace of mind.

Single Wall Stove Pipe: Features, Pros, and Cons

A single wall stove pipe is a common and affordable option for connecting a wood stove to a chimney system. While it’s easy to work with and budget-friendly, it does come with limitations—especially in terms of safety clearances and heat retention.

Design and Construction

Single wall stove pipe is made from one layer of galvanized or stainless steel, typically in a matte black finish. It’s designed to radiate heat into the room as the hot gases pass through, but it also loses more heat to the surrounding air compared to insulated systems.

These pipes are usually 22 to 24 gauge steel and come in various diameters to match your stove’s flue collar. They must be used only inside the living space and cannot penetrate walls or ceilings without transitioning to a UL-listed chimney pipe.

Advantages

-

Lower cost: Single wall pipes are significantly cheaper than double wall systems.

-

Ease of installation: Lightweight and simple to cut or adjust during DIY projects.

-

Radiant heat: Provides additional warmth to the room by releasing heat along the pipe.

-

Readily available: Compatible with most standard wood stoves and flue collars.

Drawbacks

-

Requires more clearance: NFPA 211 requires at least 18 inches of clearance from combustibles.

-

Greater heat loss: Less efficient at retaining flue temperatures, which can lead to more creosote buildup.

-

Not ideal for tight or enclosed spaces: The wider clearance zone can make installation difficult in small rooms or cabins.

-

Shorter lifespan: Tends to degrade faster over time due to direct exposure to high heat and corrosion.

Ideal Use Cases

Single wall stove pipe is best suited for:

-

Open living areas with plenty of space around the stove

-

Budget-conscious installations

-

Setups where maximum radiant heat is desired

-

Users planning to run short, straight connections to the chimney

For longer runs, or when your installation requires reduced clearance, a double wall pipe may be the better option.

Double Wall Stove Pipe: Features, Pros, and Cons

A double wall stove pipe is designed with efficiency and safety in mind, making it a preferred choice for modern wood stove installations—especially in tight spaces or colder climates. Its dual-layered construction provides better heat retention, reduced clearances, and longer lifespan, but at a higher cost.

Design and Construction

Double wall stove pipes are made with two concentric layers of steel—typically a stainless steel inner wall and a black-painted outer wall—separated by an insulating air gap. This design helps keep the outer wall cooler while maintaining high flue gas temperatures inside the pipe.

These pipes are UL 103 HT listed, making them suitable for high-temperature wood-burning appliances and compliant with NFPA 211 safety codes.

Advantages

-

Reduced clearance to combustibles: Requires only 6 inches, ideal for tight spaces or rooms with limited wall clearance.

-

Retains more heat in the flue: Improves draft, reduces creosote buildup, and increases stove efficiency.

-

Increased safety: Outer pipe stays cooler, lowering the risk of accidental burns or nearby materials overheating.

-

Durability: Resistant to warping, corrosion, and long-term wear from high heat cycles.

Drawbacks

-

Higher upfront cost: Typically 2–3 times more expensive than single wall pipe.

-

Heavier and more rigid: May require stronger wall or ceiling supports and careful installation.

-

Adapter requirements: May need transition pieces when connecting to a single wall section or stove collar.

When to Choose Double Wall Pipe

This pipe type is ideal if:

-

You need reduced clearance (e.g., small cabins, tight corners).

-

You live in a cold climate, where maintaining flue temperature is crucial.

-

You want to minimize creosote buildup and improve draft.

-

You’re focused on code compliance and long-term safety, especially in insurance-reviewed installations.

Key Comparison Factors: Single vs. Double Wall Stove Pipe

Choosing between single wall and double wall stove pipe depends on several critical factors—ranging from safety clearances to performance efficiency and installation costs. Here’s a side-by-side look at how they compare in the most important areas.

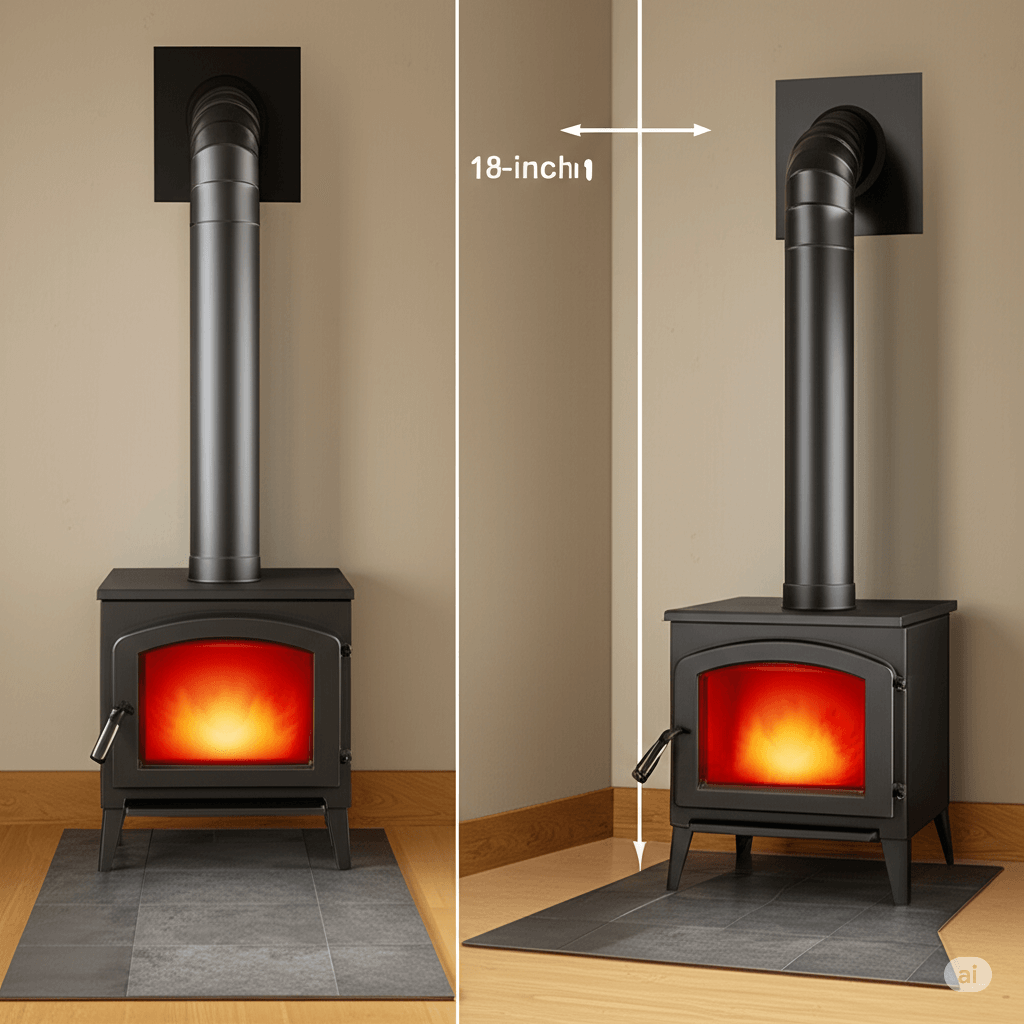

Clearance to Combustibles

-

Single Wall Pipe: Requires a minimum of 18 inches clearance from combustible materials (wood walls, furniture, etc.), as outlined in NFPA 211.

-

Double Wall Pipe: Requires only 6 inches clearance, thanks to its insulating air gap and cooler outer wall.

-

Practical Impact: Double wall pipes are better for tight spaces, corners, or areas with restricted clearance. Single wall requires more open area and careful planning to meet code.

Heat Retention and Efficiency

-

Single Wall Pipe: Loses more heat into the room, which can lower flue gas temperatures and increase creosote buildup.

-

Double Wall Pipe: Retains more heat inside the flue, maintaining better draft and reducing buildup risk.

-

Practical Impact: Double wall performs better in cold climates and reduces the frequency of cleanings.

Durability and Lifespan

-

Single Wall Pipe: Made of a single layer of steel and tends to wear out faster, especially with heavy use.

-

Double Wall Pipe: Built with two steel layers, making it more resistant to heat warping and corrosion.

-

Practical Impact: Double wall generally offers greater longevity, especially for year-round wood stove users.

Cost Considerations

-

Single Wall Pipe: Lower upfront cost and easier for DIY installations.

-

Double Wall Pipe: Higher initial investment, but often offsets with reduced clearances and improved performance.

-

Insurance Note: Some insurance providers prefer or require UL-listed double wall installations, especially in small or high-risk areas.

Installation Tips and Safety Considerations

Proper installation of your stove pipe is essential to ensuring your wood stove operates efficiently and safely. By following the right NFPA codes, using proper supports, and ensuring appropriate clearances, you can create a long-lasting, fire-safe setup. Below are key installation tips to help you achieve this.

Following NFPA and Local Building Codes

-

Always ensure your stove pipe installation meets the NFPA 211 and local building codes. These codes outline safety standards regarding clearance, pipe materials, and installation methods to prevent hazards like chimney fires and carbon monoxide buildup.

-

Check with your local authorities to ensure your installation complies with state and city-specific regulations, which might require permits or professional inspections.

Maintaining Proper Stove Pipe Clearance

-

Single Wall Pipe: Requires a minimum of 18 inches clearance from walls and other combustibles. This clearance is critical to avoid heat buildup, which can ignite nearby materials.

-

Double Wall Pipe: Only requires 6 inches clearance due to the insulating properties of the pipe. However, it’s still crucial to maintain this minimum distance to prevent damage to walls and nearby objects.

-

Practical Tip: Use a clearance gauge to double-check distances before installation to ensure you’re within code requirements.

Using the Right Adapters and Support Brackets

-

When transitioning from stove pipe to chimney pipe, always use the correct adapters to ensure a secure connection. This will prevent leaks or disconnections that could lead to dangerous smoke or carbon monoxide exposure.

-

Install support brackets to help maintain the integrity of the system. Make sure the pipe is level, well-secured, and does not sag or disconnect over time.

When to Call a Certified Chimney Sweep (CSIA)

-

Installing or upgrading your stove pipe system can be complex. If you’re unsure about installation or system maintenance, it’s always best to call a Certified Chimney Sweep (CSIA) for professional guidance.

-

A professional can help ensure your installation is safe, code-compliant, and provides maximum efficiency. They can also inspect the system regularly to prevent dangerous buildup, such as creosote.

Based on NFPA 211, proper stove pipe selection and clearance can prevent serious fire hazards.